Maybe you

want to build your own? Maybe you want to take this design and mod it for

agility, weight, or style. Awesome. First, here’s the base pattern:

Getting Started

First off,

you’ll need some tools:

·

CNC laser cutter. In theory, you could cut these parts out with an

x-acto knife, which is madness. You’ll want to borrow a laser cutter. Honestly,

you should just buy one. They’re the absolute best thing in the world, and the

prices are dropping very fast. Check out Hurricane

Laser, for example. Or TechShop.

·

Scissors, for cutting tape.

·

Soldering iron, and solder.

·

A can of Super77 spray glue.

·

60degree hole chamfer. Handheld is fine.

You’ll need

the following build materials. For my examples, I use cardboard sheeting from

ULINE.

·

Several sheets of 4mm cardboard. The thickness matters, if you change

the thickness, make sure you update the tab cutouts to match. They’re 3x the

thickness, or 12mm.

·

Brown paper packing tape for sealing the edges. The clear stuff doesn’t

stick very well. You can also use fiber reinforced tape.

·

4×4″x1/8″ black ABS plastic sheet. You can also use heavy card stock,

sheet metal, acrylic, or aluminum bar stock.

·

No. 127 Black ESD or similar. 7”x1/8″

·

One 14oz ZipLock plastic container, or other lightweight 5″ diameter

bowl.

·

Double sided copper clad PCB board, you’ll need about a 0.5×0.5″ square

piece.

·

4 paperclips.

For

electronic components, you’ll need the following:

·

4ea 22mm brushless outrunner motors. I’ve used both Cobra 1300kV and

DiyDrones 850kV motors.

·

4ea matching prop adapters for your motors and propellers.

·

4ea regular propellers. GWS 8×3, GemFan 10×45, etc. Yes, 4ea. You’ll

want extras, lots of extras. You’ll break a lot of props at first.

·

4ea reverse propellers.

·

4ea ESC controllers for your motors, with an on board BEC. I use 20A

NextLevel controllers.

·

20mm heatshrink, for the covering the copper clad power board.

Electrical tape works too.

·

6mm heatshink for covering connectors and wires.

·

0.1″ spacing jumper wires, female socket. For the battery power sense

line.

·

Controller board. I use the Quadrino Zoom.

·

Cable assembly for Quadrino Zoom.

·

Spread spectrum 2.4ghz transmitter and receiver. 6 channel or better.

Spektrum DX6i, etc. There are 4 control channels, and 2 mode channels. You’ll

need another two channels if you want to add head tracking later.

·

2-4ea, 2000-1300mAh 3S LiPo battery. Trust me, you’ll want more than

one. Your motors must match the battery voltage. I use Turnigy batteries.

·

Lipo battery charger.

·

Battery connector plug and wires. I use XT60 plugs.

·

Sparkfun Blutooth module, if you want wireless telemetry. Totally

optional.

·

Nylon mesh wire sleeve. I use this to protect the motor leads from prop

strikes. Also optional.

It’s a lot

of parts and pieces, it’s true. Depending on where you source things from, and

how fast your shipping times are, it can take up to a month for all the parts

and pieces to arrive. HobbyKing has notoriously long wait times, for example.

If you care about customer service and speed, order domestic. I recommend Innov8tive Designs.

Got all your

parts and pieces? Great! Let’s get started…

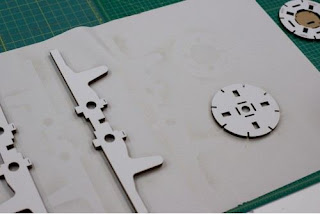

Step One – Cut The Pieces Out

The major

consideration when cutting out the corrugated paper parts is to make sure the

corrugation pattern runs it different directions for the different layers. This

helps to create an internal truss structure and makes the beam considerably

stronger once assembled. Note also, that how evenly the layers are glued

together will affect the strength of the beam dramatically.

The

corrugation patterns should look like so when they’re all stacked up.

Sometimes, as is in the case of parts from ponoko, you may not be able to get

the corrugation pattern to line the way you want it to. This is okay. The order

and direction of the layers isn’t that crucial, just that they change angle

between layers.

For the

motor mounts, which are just little tabs that screw into the back side of the

motor, I used ABS. It cuts great on a laser, usually in a couple passes. ABS is

extremely impact resistant, but it does have two undesirable properties: it

smells really bad when cut, and it’s susceptible to long term UV damage. Use

proper ventilation, and wait a few minutes after your done cutting before

opening the laser bed door. It will smell for a few days, but eventually will

be tolerable.

The motor

mounts can be made out of pretty much anything, you could use aluminum bar

stock from the hardware store, and drill out the motor mount screw holes. You

could laser cut heavy tag board, or acrylic. Anything that is reasonably stiff

will work. You could even use 1/8″ plywood, but ABS or aluminum will last the

longest.

Step Two – Glue It Together

Next up we

glue the pieces together. I use Super77 spray adhesive, which Joachim points

out in the previous Tricopter build post, is expensive. It’s also not as strong

as paper glue, but in practice, it really doesn’t matter all that much. In the

15 or so frames I’ve built so far, none has ever failed.

As the arm

layers are symmetric, it’s possible to have all the exterior faces show the

white side of the cardboard outward. Start by labeling the two middle arm

layers, they’re the ones with the horizontal or vertical corrugation pattern.

Placing them down, brown side up, along with two of the four outside layers, on

a sheet of newsprint. Set the other two outside layers aside, we won’t be

spraying them with glue. Spray the four total arm pieces with Super77.

To give

myself a little wiggling room, I don’t wait until it’s dry before I carefully

pick up the middle piece and place them each on their matching outside layer.

Alignment is important, if the arms are misaligned it will be harder to mount

the motors vertically later. If one of the motors is tilted slightly, it will

cause minor yaw drift. You can usually trim this out in the controller though.

Make sure you check the alignment of the notch corners.

Remember, it’s an accuracy test, not a speed

test

Then we

spray one side of the bottom plate layers, and the underside of the upper top

plate layer with glue. Again, alignment is important. While the orientation of

the bottom plate doesn’t matter too much, make sure that the quadrino wire

holes are oriented down, and that the label for motor A is in the upper left

corner. Otherwise the labels will be wrong.

Step Three – Tape The Edges

This is an

important step. The edges of cardboard aren’t particularly strong. To keep them

from getting crushed and damaged over time, we need to place tape across them.

The type of tape we use is also important. A paper gum tape is the best. This

is the kind where you wet one side with a sponge to make it sticky, like a

stamp. As an added bonus feature, it comes in white. You’ll want to use a gum

tape if you’re going to coat the frame in polyurethane or resin later. Coatings

will dramatically increase the stiffness and strength of the frame, at the

expense of a little bit more weight. You can also use a craft paper and glue in

lieu of tape.

If you’re

not going to coat the frame, use brown paper boxing tape. Avoid clear boxing

tape, it’s terrible and comes undone easily. The brown paper boxing tape is

very strong.

Start by

taping the top edges, and on the undersides. For the motor mount area I wrap an

extra layer of tape around the arm. I also cover the feet, as they take a lot

of impact.

Put a tiny

little piece of tape over each tab, and re-cut the paperclip slit with a knife.

This will make the tabs easier to insert without them getting damaged.

Once all the

tabs and edges ares taped, we’re ready to assemble the frame. Slot the arms

together, and push them gently into the upper plate. Add a pair of paper clips,

and set the bottom plate aside. To make the paper clips easier to remove later,

I bend them up at 90 degrees on one side, and then slot them in.

Step Four – Solder The ESCs

I use a tiny

copper board to solder all the ESCs together. You can also strip the wires a

little more, and solder them all together. If you do this, wrap the bundle

together with some thin, bare copper wire. It will make soldering the mess

together much, much easier. The most important thing, is to have two of the

ESCs pointed in one direction, and two pointed in the other.

I then solder on the battery connector whip, and add two motor controllers. After it cools, I slide a piece of the large heatshrink down over the wires, and out of the way. Then I solder the remaining two motor controllers and a small 22AWG red wire to the positive rail.

The little

red wire will be used for on-board voltage sensing by the controller. If you

bought female 0.1″ spacing jumper wires, use one of these. After that cools, I

slide the heatshrink over the whole mess and shrink it down. Viola! A nice

little power distribution board

I put nylon

mesh jackets on the motor lead wires. This helps keep them neat and tidy, and

protects the leads from prop strikes and other mishaps.

Step Five – Attach The Motors

I put nylon

mesh jackets on the motor lead wires. This helps keep them neat and tidy, and

protects the leads from prop strikes and other mishaps.

As your

motors probably didn’t come with the 3mm bullet connectors, you’ll want to

solder them on now. I use a little piece of cardboard with holes punched in it

to keep them stead while soldering. Drilling into a block of wood also works

well too. Careful, if you put them in a metal vice it will make it very

difficult to heat the connector and wire up.

Unlike most multi-rotor designs, the thing this one lacks is screws. Except for the motor mounts, pretty much no way out of that. This is important because screws, bolts and standoffs can add a lot to the cost of a frame. There are a lot of different ways to construct the motor mounts, but what’s most important is that there be two flat tabs sticking out from under the motor that are about 0.5″ or 12mm wide which we can use to tape the motor onto the arm. I can hear you now: “tape?” If you use the right tape, it works amazingly well.

The first step

is to use the hole chamfer to but a bevel in the the motor screw holes one one

side. The next step is also important: on the other side, taper the center hole

slightly. This is important as otherwise the shaft snap collar on the motor

will brush against the motor mount and you’ll see a lot of yaw drift in flight.

Attach the motor mounts to the underside of the motors, and put a little Lock-Tight in the screw holes. Without it, they’re pretty much guaranteed to vibrate out in flight, sending you on a quick trip to the hardware store for a somewhat rare 3mm machine screw

.

Place them

at the end of each arm and tape them down tight. If they’re

taped on loosely the extra play will get larger over time from vibration. If

they’re tight they’ll stay put for a very long time.

Step Six – Finishing

The remainder of the build involves rubber bands. Lots of rubber bands. I use 7″x1/8″ No. 127 Platinum Crepe brand black rubber bands to attach components, hold on batteries, and keep things put. They’re very fast to add and remove, and unlike zip-ties, they’re reusable.

I use four

rubber bands to secure the motor lead wires to the arm. Hook it onto the

landing leg, wrap it around twice, and loop it over the same leg.

Another two to hold the ESCs in place. It goes from one side, to the other.

One to hold

the battery pack on. This one has to be attached while the plate is removed,

after that you just pull on the middle section and slide a battery in. If you

have a particularly heavy battery add two rubber bands. One will probably be

enough.

One more to

hold the controller in place. Be careful to avoid resting the rubber band on

the pins, it’s under enough tension to either bend the pins, or snap the rubber

band due to vibration. Notice those four little holes in the top plate? They’re

for nylon screws, you can optionally add them to help keep the controller board

on axis. In practice though, the rubber band should be enough.

Step Seven – Software Setup

I chose the

Quadrino Zoom, which is about mid-range price-wise, because it has a full 10DOF

sensor platform, and is very well laid out. Flying with mag-lock is great for

beginners and lets you fly without having to worry about craft orientation. I

wish it had a built in buzzer, and an on-board current sensor, but it’s a very

nice out of box experience as far as controllers go.

Once you

download the multiwii software and open it up in Arduino, head on over to the config.h file and

change a few important things.

·

#define QUADX // our flight configuration

·

#define QUADRINO_ZOOM // our controller

·

#define MOTOR_STOP // this will keep the props spun down when throttle

is at a minimum. Useful for throttle cut when you’re first crashing^H^Hlearning

to fly.

You’ll also

need to set the minimum ESC engage threshold. Again, see the MultiWii site for

that howto.

Go Fly!